Green Oxidation with Aqueous Hydrogen Peroxide

【清洁技术】利用过氧化氢进行氧化反应不产生副产物

Kazuhiko Sato

Research Institute for Innovation in Sustainable Chemistry,

National Institute of Advanced Industrial Science and Technology (AIST)

More than 30 percent of all chemical processes in the world include oxidation process among them;

therefore, oxidation processes play one of critical roles in our chemical industries today. Unfortunately

those important processes are not environmentally friendly. For example, nitric acid, an oxidant

generally used for mass-scale oxidation in industry, concomitantly produces notorious greenhouse

gases, nitrous oxide and nitrogen oxide (NOx), as by-products. Heavy metals such as chromium used

for high selective oxidation processes produce heavy metal waste more than equivalent amount of the

target products. In this paper we describe our effective and selective oxidation technologies using

hydrogen peroxide, an environmentally friendly oxidant, and their application to development of

innovative high-insulation materials.

Hydrogen peroxide (H2O2) is a water-soluble liquid oxidant commonly used in our daily lives as

low-concentration aqueous solution (disinfectant Oxydol, contact lens cleaner, etc.). It is also used as

non-chlorine bleach powder and washing machine cleaners in the solid form safely combined with

several inorganic substances. Hydrogen peroxide is a safe and clean oxidizing agent, producing only

water as its by-product through oxidation process. Despite this great advantage, its activity as oxidant

is not so strong that it requires some activating reagents to oxidize compounds of petroleum industry.

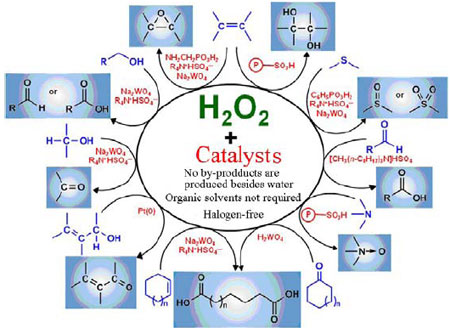

We have discovered a lot of new catalytic systems that dramatically enhance the oxidation activity of

hydrogen peroxide. These oxidation systems are elaborately developed for each transformation to

obtain aiming products with high yield and high selectivity, and without producing any hazardous

by-products. (See figure 1. Catalysts written in red.)

Figure 1 Selective oxidative reactions using hydrogen peroxide

In spite of our effort there have been a lot of difficulties we encountered chemically and

non-chemically so far for applying some of our systems to the real industrial processes for commercial

products. However, we have achieved some goals with our system. Here is an overview of NEDO

project to introduce one of our successful examples in Joint R&D with Showa Denko K.K. where

collaboration of our chlorine-free epoxidation technology and Showa Denko’s hardening reagent

technology has sublimed to development of an innovative insulating material that can be used for

next-generation electronic products. Insulating material is used for all kinds of electronic components,

from liquid-crystal displays (LCDs) to mobile phones. General insulating materials are made from

epoxy resins and the resins are conventionally made from organochloride compounds. The latter

process produces a large amount of chlorine compounds as waste. Additionally, even a negligible

amount of the initial organochloride remained in the insulating material causes hydrogen chloride

during its long term use, ending up with short-circuit. This has been a significant problem for the

durability of conventional insulators. For providing lightweight, high performance electronic devices,

it is now inevitable to develop technologies for creating more flexible print circuits and microscopic

wiring technique. Hence, insulating material with high flexibility and durability are, at the same time,

highly demanded for protecting these sensitive circuits safely. We have successfully developed a new

catalytic system for epoxidation that meets high demands; 1) mono-epoxidation of compound across

its one of two olefinic moieties, which has been designed for electronic material use, with high yield

and selectivity, 2) being applicable to mass-production and 3) using aqueous hydrogen peroxide as

oxidant. Our catalytic system was successfully carried out for the chlorine-free epoxidation on the 100

kg scale. Finally, combination of oligomers obtained from our epoxy monomers and well-tuned

hardening agents from Showa Denko realized high-performance flexible resin (insulating material).

This material showed extremely higher insulation capability (>×102) than conventional one and

maintained the capability for very long-term use without any deterioration. Now, this material has

been used as high flexible insulator for COF (see Figure 2). With this material we can make products

such as LCDs slimmer, more lightweight and highly energy-saving.

Figure 2 Sample of COF (Chip-on-Film)

The success in the Joint Research has opened up an opportunity for us to start the new national

project, “Development of Fundamental Technologies for Green and Sustainable Chemical Processes”

directed by the Ministry of Economy Trade and Industry from 2008. This project was ranked as “S”

(“Selected Priority Project”) by the Council for Science and Technology Policy (CSTP). Our green

chemical technologies, which include hydrogen peroxide technology, were also selected as innovative

technologies by CSTP. We have set up intensive R&D lab at AIST for developing next basic

technologies toward innovative green oxidation process collaborating with four companies since

September 2008. Some of our systems are also being employed as part of educational curriculums at

universities and other institutions to learn what the green chemistry is (e.g. “Let’s Experience Green

Chemistry!” at the National Museum of Emerging Science and Technology [Miraikan]).

| < 上页 | 下页 > |

|---|